Improper 2-stroke carburetor tuning will have a much more significant effect on a 2-stroke engine than a 4-stroke because the premixed oil lubricates the crankshaft. Poor Running at High Speed.

Diagnosing the Ignition System.

2 stroke carburetor troubleshooting. Troubleshooting in Two-Stroke Engine Carburetor and Possible Solutions Unsteady or abrupt acceleration. Excessive choke during starting. White or light grey spark plugs.

Excessive or white smoke. Your motorcycle carburetor will have a slow speed pilot circuit fuel or air adjusting screw. As needed with your two-cycle engines Diagnosing the Fuel System.

Remove the air system. Spray starter fluid into the carburetor. Pull on the starter rope.

Diagnosing the Ignition System. Replace the spark plug. Test the ignition coil.

Pull on the starter rope. Learn how to disassemble clean and reassemble a 2 cycle engine carburetor with the help of this tool repair videoFor carburetor and other Small Engine Par. Remove line at carb.

And check for fuel flow. Clean filter on tank valve. Make sure gas is not over rich with too much 2 cycle oil.

16 to 1 ratio with a brand new engine and 25 to 1 with a used engine. If Old gas replace with fresh gasoil mix. If no start go to step 9.

Check for air leaks at carburetor intake manifold tube. Check for loose manifold nuts check for loose carburetor on intake manifold check for damaged intake gasket. Check float by removing float bowl from the bottom of the carburetor.

Inspect float for any cracks or holes. Mark is here to walk you through the steps needed when diagnosing your two-cycle engine issues. These steps will be the same for all the two-cycle tools in y.

2-Stroke Carburetor Main Jet Why Proper Carb Tuning Is Critical For 2-Stroke Engines. Improper 2-stroke carburetor tuning will have a much more significant effect on a 2-stroke engine than a 4-stroke because the premixed oil lubricates the crankshaft. A rich mixture will cause poor performance but a lean mixture can destroy your engine over time.

A new carburetor should preclude that unless you mean a used carburetor new to this machine. As concerns valves in 2-cycle engines there is a reed valve that is a flap of spring steel over a port. The fuel mixture can be pulled through it into the crankcase but the valve closes when the pressure in the crankcase rises as the piston is on the downward stroke.

A clean working carburetor ensures a healthy fuel economy and emissions for years. However a lousy carburetor may cause a multitude of problems with your engine such as rough idle stalling flooding poor fuel economy and hard starting. I have spent over 20 years rebuilding carburetors for many different types of applications.

Observe the pump jet in the carburetor and with your hand work the carburetor throttle to the wide-open position. You should observe a healthy squirt of fuel from the pump jet. A single barrel carburetor will normally squirt a single stream.

While a two or four barrel carburetor will normally squirt 2 streams. 2-stroke engines dont have a sump reservoir containing oil. If the trimmer is 4-stroke you can follow the procedure outlined in Jacks Small Engines here or check your manual for the procedure for your specific model.

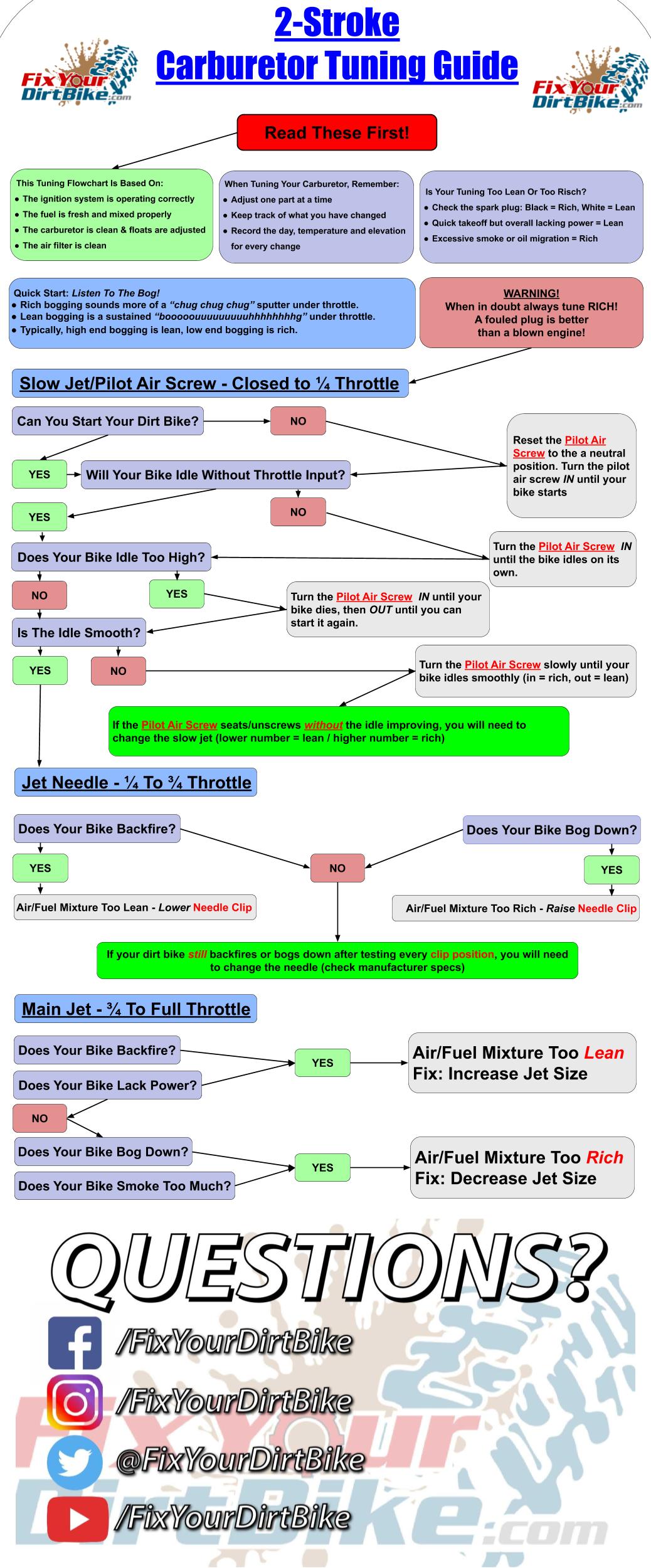

If you can give me the model number I can check the details. Two-Stroke Motorcycle Troubleshooting Guide Engine Doesnt Start. Poor Running at Low Speed.

Poor Running at High Speed. Spark plug fouled broken or misgapped. Clutch Not Working Properly.

On two stroke carburetors this is an airscrew so dont forget turning the screw out is a leanermixture. Using the throttle keep the engine at a low RPM just above stall RPM. Use the throttle to slightly increase and decrease the RPM.

2 Stroke Engine Troubleshooting - Air. Checking to make sure your engine is getting air is the easiest part. Typically just a visual inspection of the air filter and carburetor area is all it takes.

Air is usually never the problem. I have only once in my life experienced air being the problem with a 2 stroke engine not starting. Carburetor problems generally fall into three areas.

Too lean a mixture too rich a mixture or an incorrect adjustment. Luckily there are telltale symptoms that will tell you which problem youre dealing with. Carburetors are relatively simple devices.

Their primary function is to deliver the right amount of fuelair mixture at a given. Properly cleaning a 2-cycle engine carburetor means completely disassembling and reassembling the unit. We explain the steps to disassemble and reassemble an example 2-cycle engine carburetor below and we also explain the correct way to clean a carburetor while its still disassembled.

Remove the Carburetor Use a socket or nut driver to remove the two bolts that hold the carburetor to the engine. Unhook the throttle cable from the carburetor linkage. Place the carburetor in a container to catch the gas.

On some 2-stroke carburetors there is a small priming bulb that allows you to create a vacuum much like the engine would to pull fuel into the carburetor. When these collapse or crack they dont function properly and must be replaced. They are not all the same size so you need to get one specifically for your carburetor.