Aftermarket aluminium heads have unique torque settings so manufacturers guides should be consulted. Discussion Starter 1 Aug 8 2019.

Short Bolts 347811121516 Additional.

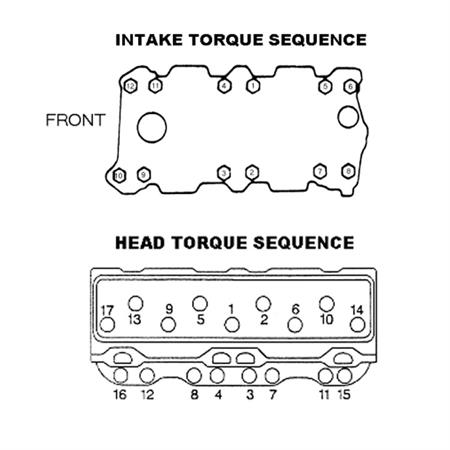

350 head bolt torque. While the first generation 350s 65 ft-lb. Head bolt torque is one of those numbers that all real gearheads have committed to memory the bolt tightening sequence is a little more complex. Assign each of the three rows of bolts a letter from top intake manifold side to bottom exhaust manifold side.

A for the top B for the middle and C for the bottom. By Staff Writer Last Updated Mar 26 2020 54033 AM ET. The torque specifications for Chevrolet 350 cubic inch V8 head bolts are 65 foot-pounds per bolt if securing the stock cast iron head.

Aftermarket aluminium heads have unique torque settings so manufacturers guides should be consulted. The tightening of Chevy 350 cylinder head bolts must always be done in a helical sequence starting from the center bolt and working outwards in a clockwise spiral. 350 head bolts torque.

Jump to Latest Follow 1 - 20 of 20 Posts. Joined Jul 14 2019 28 Posts. Discussion Starter 1 Aug 8 2019.

I have a Targetmaster 350 GMC with the made in Mexico heads had a head gasket leak so replaced and finding different torque specs some say 65 lbs some say 75 anyone know. Main-cap torque specification on the typical Chevrolet 350 two-bolt-main engine is 70 ft-lbs. Specifications for the four-bolt-main are 70 ft-lbs for the inner bolts 65 ft-lbs for the 716-inch outer bolts and 40 ft.

For the 38-inch outer bolts. The connecting-rod torque specifications are 40 to 45 ft-lbs. For 38-inch bolts and 35 to 45 ft.

Torque Specifications for GM 57L-350ci-V8. Bell Housing To Engine Block. These specs are for stock-type bolts with light engine oil applied to the threads and the.

SBC Crank Main Caps and Rod Bolts. Main bearing caps on 327 engines should be torque in two steps to between 60 and 70 lb-ft while 350 engines should be taken to 75. These are the caps on the crankshaft.

Rod caps or rod bearing caps should be torqued to 45 lb-ft for the 327 engine and 35 for the 350 engine. This is the Head Bolt Torque Sequence Pattern for the Small Blocks Mouse Motors. Or what ever you might lovingly call this motor.

I have not had a lot of vehicles with Small Block Chevys other then. My engine swap 372 Motor I put into my International Scout. This does not include specs for LSX or Aluminum.

The BoxWrench Engine Specs Database is a community resource for mechanics of all skill levels to. The most important operation of regasketing your engine is thorough cleaning of the. Todays critical - head studs and bolts main studs and bolts and driveline - have been designed stronger than ever before to handle the extreme loads.

As a results installation pre-loads - the amount the fastener is stretched during installation - are very high. Fastener Assembly Lube Basics. I honestly would not make this video if i havent seen someone forget to seal these bolts this is a must as a bonus i will show you guys how to torque these b.

Carefully guide the cylinder head into position over the dowel pins and gasket. Coat threads of the head bolts with sealing compound and finger tighten all bolts. Tighten all bolts in sequence to 22 ft.

Tighten all bolts in sequence an additional turn in degrees using J 36660 tool. Short Bolts 347811121516 Additional. CYLINDER HEADVALVE TORQUE VALUES Rocker arm shaft retaining bolt 7 Nm 07 kgfm 51 lbfft Cylinder head cap nut 39 Nm 40 kgfm 29 lbfft Apply oil to the threads and seating surface Rocker arm holder bolt 30 Nm 31 kgfm 22 lbfft Apply oil to the threads and seating surface Cam chain tensioner slider pivot bolt 12 N.

Ford Super Duty Torque Specifications 2000 Ford F250 Torque Specifications. These are torque values for a 2000 Ford truck. Most will be applicable to model years 1999-2003.

Torque Specs Sequences and Alignment - Covers 221 260 289 302 Boss 302 351W 351C 351M and 400M Small Block Ford Engines. Buick 350 Engine Specifications and Blueprinting. General Specifications for the 1970 Buick 35 Cubic Inch Engines.

The following information has been directly complied from original 1970 Buick service manual. Head bolt torque pattern for Buick 300-340 engines. In some cases the stretching approaches the bolts elastic limit permanently stretching them.

Reusing stretched T-T-Y head bolts can cause improper or uneven torque damaged engine threads and broken bolts any of which could lead to head gasket failure. It is important to use new bolts and proper torquing procedures during reassembly.