ARP is adamant about using a special moly lube or ARP thread sealer for use with their stud packages. The piston caps have two bolts per piston that require specific torque.

To compensate for lubrication torque values are often reduced by about 10 to 25 percent.

350 head torque specs. 350 Chevy Head Bolt Torque Specifications Original Small Block. While the first generation 350s 65 ft-lb. Head bolt torque is one of those numbers that all real.

All 1995 and earlier LT-series engines use the same head bolt torque 65 ft-lb and tightening. The torque specifications for Chevrolet 350 cubic inch V8 head bolts are 65 foot-pounds per bolt if securing the stock cast iron head. Aftermarket aluminium heads have unique torque settings so manufacturers guides should be consulted.

Torque Specifications for GM 57L-350ci-V8. Bell Housing To Engine Block. Torque Specifications for a Chevy 350 Lower Engine Components.

The piston caps have two bolts per piston that require specific torque. You will also need to. Main-cap torque specification on the typical Chevrolet 350 two-bolt-main engine is 70 ft-lbs.

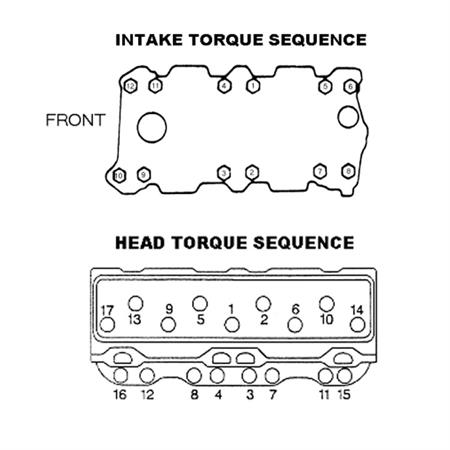

Small Block Chevy Head Bolt Torque Specifications. Step 1 25 FtLbs. Step 2 45 FtLbs.

Step 3 65 FtLbs. For Head Studs or aftermarket bolts CHECK YOUR INSTRUCTIONS SBC studs are available in a ton of. Different styles depending on.

The BoxWrench Engine Specs Database is a community resource for mechanics of all skill levels to access a reference library of Firing Orders Distributor Rotation Directions and Block-Cylinder Numbering as well as Torque Specs Timing Settings and Cylinder Head Tightening Sequences among other engine specs. These specs are for stock-type bolts with light engine oil applied to the threads and the. Other than from the inside out there are no torque specs I could find for any of the Ford engine exhaust manifolds.

Some of the Ford-heads I know tell me that 20-25 lb-ft for the 289 and 302 engines and 30-35 for the 351 is fine. They also mention that copper gaskets with high-temp exhaust spray gasket sealer should be used. Ford Rod Bearing Caps and Main Bearing Caps.

Bolting down the heads in this episode. Torque sequence as followsFirst Pass torque to 22 ftlbsSecond pass tighten short bolts 55 degrees medium bolts 65. Place head bolt washers over each bolt hole.

Once they are in place put a small amount of ARP moly lube on the tops of all washers. Coat all threads with Permatex 3H Aviation Form-a-Gasket follow Permatexs directions for set-up time then place the bolts in their proper locations. Torque the bolts in the three stages.

Mack E7 engine Power Torque Power E7-250 250 hp 186 kW 1950 rpm E7-350 350 hp 261 kW 1800 rpm E7-460 460 hp 343 kW 1950 rpm Torque E7-250 975 lbft 1306 Nm 1200 rpm E7-350 1277 lbft 1711 Nm 1250 rpm E7-460 1660 lbft 2224 Nm 1200 rpm. Head bolt sorque sequence The use of studs offers greater clamping force and also requires a torque sequence and lubricant as recommended by the manufacturer. ARP is adamant about using a special moly lube or ARP thread sealer for use with their stud packages.

ALWAYS follow the manufacturers instructions for best results. A dirty bolt can throw off torque readings by as much as 20 ft. 2 Watch bolt lengths.

Head bolts on some engines vary in length and it is important that these bolts be replaced in their original location. 3 Head bolts that enter the water jacket of the engine should have sealer applied to the threads. Bolt main bearing cap to block 70 lb-ft 100 lb-ft oil 20 lb-ft Bolt rear main cap to block 100 120 oil 20 Bolt cylinder head 85 95 oil 20 Bolt flywheel to crankshaft 95 95 dry 40 Bolt oil pan to block 12 12.

I just bought a brand new digital torque wrench set it to 72 ft lbs to tighten the spring bolts on my raptor 350 clutch and Ive snapped the heads off the bolts 3 times. Torque Specs Sequences and Alignment - Covers 221 260 289 302 Boss 302 351W 351C 351M and 400M Small Block Ford Engines. Then in 1967 Chevy had a big year with the release of the 302 and 350 engines.

The 302 still used a 4-inch bore but had a shorter 3-inch stroke like the 283 affording a much higher-winding race engine. The 350 blocks used the same 4-inch bore as the 327s except they increased the stroke to 3480-inches. To compensate for lubrication torque values are often reduced by about 10 to 25 percent.

This reduction may not be required for the small under 14 inch high-quality fasteners. Refer to the Sidebar Bolt Torquing Techniques on page 120 for more information before applying the torque specifications listed on this page or elsewhere in.