This can be determined by rotating the pushrod while turning the adjusting nut. The Chevrolet Big Block is a term for a series of large displacement V8 engines that have been developed and produced in the United States from the 1950s until 2009.

Adjusting Hydraulic Lifters for Proper Preload In order to adjust the preload the lifter must be properly located on the base circle or Heel of the lobe.

Big block chevy valve adjustment. Small and big block Chevrolet engines use a firing order of 1-8-4-3-6-5-7-2. What you are going to do is separate the order into the two sides of the firing order. These are exact opposites that put the opposing valve at the correct location for adjustment meaning the back side base circle or heell of the cam lobe see image at left.

Rotate Clockwise to 40 BTDC Adjust 1 cyl Exhaust Valve. Rotate Clockwise to 20 BTDC Adjust 2 cyl Intake Valve. With MY cam If I were to use the 1 TDC method the 8 Exh valve would be 50 off of valve center line the 2 Int valve would be 20 off of valve canter line.

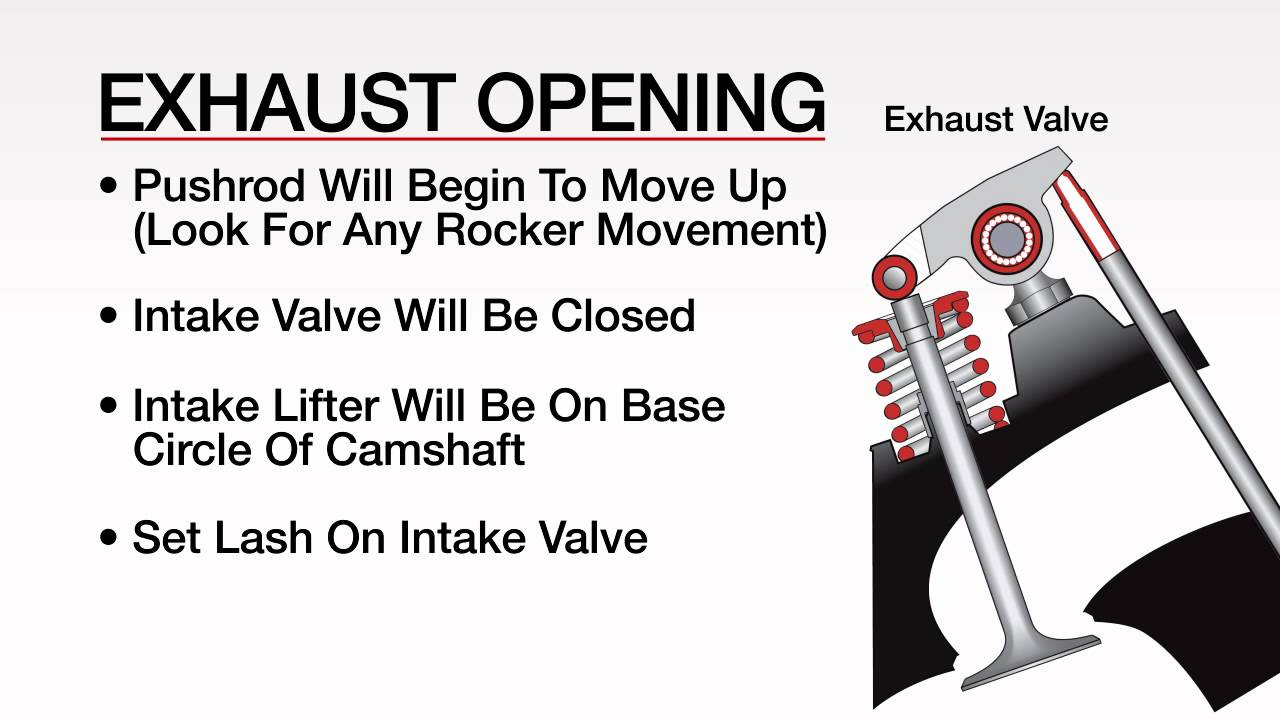

When the exhaust valve just begins to open on the first cylinder in the firing order adjust the intake valve by loosening the adjusting nut slightly while spinning the pushrod until you feel lash in the rocker arm. Tighten the adjusting nut until the slack is taken out of the rocker arm and pushrod. We upgrade the cooling system in our big-blockpowered 1967 Camaro using a Frostbite aluminum radiator dual SPAL electric fans and a Weiand water pump.

Read More Junkyard 48L LS makes 672. How to adjust Hydraulic valves first time every time. Ill show you how to adjust your hydraulic valves or lifters the easy way.

This is a very easy method that never fails. This valve adjustment technique wor. Back out the adjusting nut until lash is felt at the pushrod then turn in the adjusting nut until all lash is removed.

This can be determined by rotating the pushrod while turning the adjusting nut. When the play has been removed turn the adjusting nut 360 or one full additional turn in order to center the valve lifter plunger. Rotate the engine clockwise 90 as you face the engine and adjust 8 valves.

Rotate the engine another 90 clockwise adjust 4 valves and so on through the firing order. At TDC on each cylinder the overwhelmingly vast amount of cams will have each cylinders cam lobes in the correct position for adjustment. Adjusting Hydraulic Lifters for Proper Preload In order to adjust the preload the lifter must be properly located on the base circle or Heel of the lobe.

At this position the valve is closed and there is no lift taking place. You will need to watch the movement of the valves to determine which lifter is properly positioned for adjusting. Wait ten seconds and then adjust the rocker arm nut 14 turn.

Repeat till you have achieved your final adjustment goal 14 or 12 or 34 or 1 turn. Now for my advertising. I make a special valve cover for adjusting SBC small block Chevy hydraulic lifters I call the Adjust-A-Cover.

Also be aware that there are both 38-inch and 716-inch studs available for a small-block Chevy. Most stock or mild performance applications use a 38-inch stud. The best studs come from ARP.

Move to the number two cylinder in the firing order and the intake valve should already be open. Then rotate the engine over another 90 degrees or 14 turn clockwise while watching the lifters to ensure youre on the base circle of the camshaft lobe and repeat the adjustment procedure. To do this measure the distance from the bottom of the valvespring retainer to the top of the valve seal.

Then add 0090 inch to the measurement. The number should still be larger than the maximum. The Chevrolet Big Block is a term for a series of large displacement V8 engines that have been developed and produced in the United States from the 1950s until 2009.

As American automobiles grew in size and weight following the Second World War the engines powering them had to keep paceChevrolet had introduced its popular small block V8 in 1955 but needed something larger to power its. To adjust the exhaust valves a similar procedure is used. Turn the engine over until the intake pushrod moves all the way up.

Rotate just past maximum lift where the intake will begin to close. Have your buddy hold the rocker down against the valve stem while you jiggle the pushrod up and down to remove all play all the while slowly turning the adjusting nut to remove the play. When all the play is removed tighten the nut another 18 turn.

Move on to the other valve on 8 and do the same. Setting valves cold with hot lash settings. The mechanical cam is alive and thriving thank you.

While Crane offers an outstanding hydraulic roller lifter that weve done a story on where we pushed a big-block Chevy happily to 7500 rpm with juice lifters this doesnt foreshadow the end of mechanical lifter.