Long studs into the bottom of each cylinder head. Screw four 8mm 2725 in.

Screw the remaining studs into the block HAND TIGHT ONLY.

Head stud torque specs. This is information that you can never find when you need it so here is a table for the ARP Head. Of the bolt proof loads specified for SAE J-429 Grade 5 and ASTM A-449 bolts. Clamp loads for Grade C lock.

Nuts equal 75. Of the bolt proof loads specified for SAE J-429 Grade 8 and ASTM A-354 Grade BD bolts. IFI-100 does not.

Govern lock nuts. The values shown in the chart are to be used as a mid-range guideline. Todays critical - head studs and bolts main studs and bolts and driveline - have been designed stronger than ever before to handle the extreme loads.

As a results installation pre-loads - the amount the fastener is stretched during installation - are very high. ARP provides torque specs for our fasteners based on using ARP Ultra-Torque. 22ft-lbs 264in-lbs Then to 61ft-lbs 732in-lbs final spec 90-93 Teg B16s BUY PARTS ARP HEAD BOLTSALL B-SERIES lube top nut threads only with 10w30 or ARP Molly lube then use a 516 allen key to torque bolt studs to 10ft lbs into the block Torque arp nuts in steps.

30ft-lbs 360in- lbs60ft lbs 720in-lbs Then finally 80ft-lbs 960in-lbs. L-Head AluminumCast Sleeve Single Cylinder. L-Head AluminumCast Sleeve Single Cylinder.

L-Head AluminumCast Sleeve Single Cylinder. L-Head Cast Iron Single Cylinder. L-Head Cast Iron Single Cylinder.

L-Head Cast Iron Single Cylinder. 50 torque OK lets just say 35 FtLbs then final round at specs. For Head Studs or aftermarket bolts CHECK YOUR INSTRUCTIONS BBC studs are available in a ton of different.

Styles depending on heads and stud diameter 716 and 12. For what ever you use make sure the threads in the block are clean. It doesnt hurt to run a tap on every bolt hole.

Tightening Torque in-lbs through M8. M10 over ft-lbs METRIC FASTENERS Nominal Size or Basic Screw Dia. Threads per inch Tensile Stress Area sq.

In ASTM A574 Clamp Load lbs Tightening Torque K 015 K 017 K 020 Coarse Thread Series 1 00730 64 00026 275 30 in-lbs 34 in-lbs 40 in-lbs 2 00860 56 00037 388 50 57 67. You have to torque a given boltstud close to the yield strength of the material used or the stretch yield will allow the head to move too much and end with a blown head gasket. The best way to torque rod bolts is actually with a micrometer to measure the stretch as the thread finish or amount of lubricant used can alter the amount of strain.

Tighten bolts 1 through 10 to 180 lb-ft. Tighten bolts 1 through 10 to 210 lb-ft. Tighten bolts 11 through 15 to 24 Nm 18 lb-ft.

Tighten bolts 11 through 15 to 31 Nm 23 lb-ft Injector Clam Bolt Torque- 26ftlb depending on installer Elite uses 36ftlb. Recommended torque is equal to 75 of the fasteners yield strength. Simply read down to the correct fastener size then across to find the torque value for your application.

Always use ARP Ultra-Torque and follow the instructions below to ensure the correct preload is created. Apply ARP Ultra-Torque to fastener threads and the underhead of the bolt or underside of the nut. Need head bolt torque specs for model 205432 please.

Tighten the M8 cylinder head bolts11-15 to 22LbFt. Begin with the center bolt11 and alternating side-to-side work outward tightening all of the bolts. This video will show you how to use a torque wrench in case you need it.

Screw four 8mm 2725 in. Long studs into the bottom of each cylinder head. Screw the remaining studs into the block HAND TIGHT ONLY.

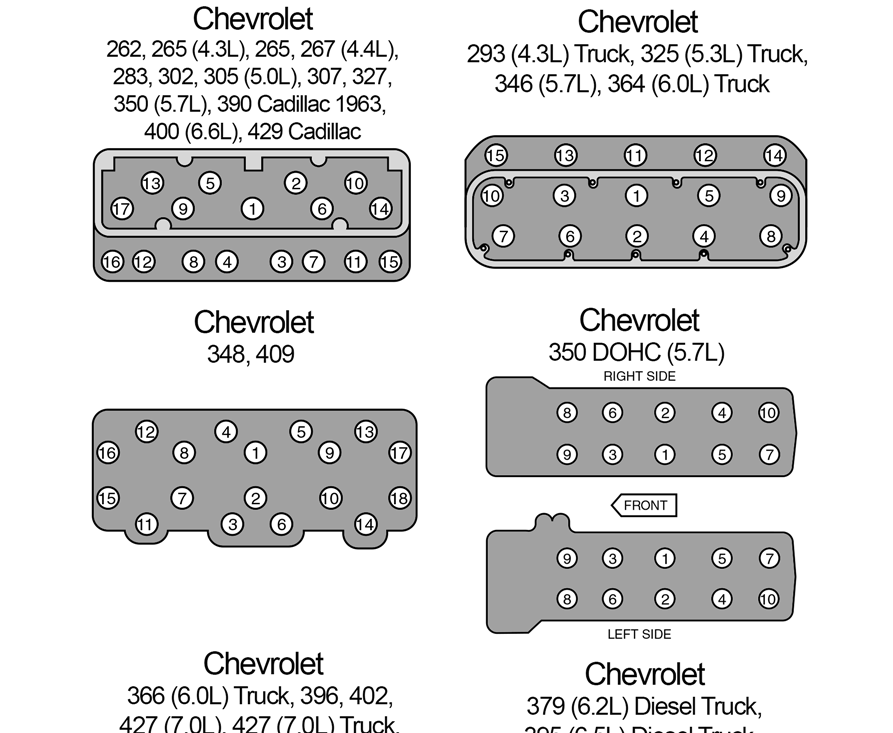

Please refer to the head stud and washer mounting location chart and the bolt torque sequence diagram listed below. LOCTITE MAY BE USED IF A PERMANENT MOUNTING OF THE STUDS IS PREFERRED. These specs are for stock-type bolts with light engine oil applied to the threads and the.

Torque Specifications for GM 53L-326ci-V8. Bell Housing To Engine Block. Chevrolet LS Gen III LS Series small block 2003 earlier two lengths ARP2000 12pt.

Chevrolet LSA ARP2000 hex. Chevrolet LS Gen III LS Series small block 2004 later - except LS9 w all same length bolts ARP2000 hex. M11 x 20 x 1555.

M8 x 125 x 460–22 ft-lbs. Rocker Arm Bolts–. Fasteners that list an angle are Torque to Yield TTY.

The specs listed are for stock fasteners. If you use ARP fasteners. Using the correct torque specifications is important.

Not enough torque and your bolt will be in a position to absorb the hits versus simply transferring the load when theres not enough clamping force applied. Too much torque and you risk damaging threads and causing other sorts of headaches. 50HO 302 Intake Manifold Torque Specs.