The intake gaskets are already installed into the manifold. Chevy SB shown on this videoDisclaimer.

Intake Manifold Bolts First Pass in Sequence 5 Nm 44 lb in Intake Manifold Bolts Final Pass in Sequence 10 Nm 89 lb in Intake Manifold Sight Shield Bolts 10 Nm 89 lb in.

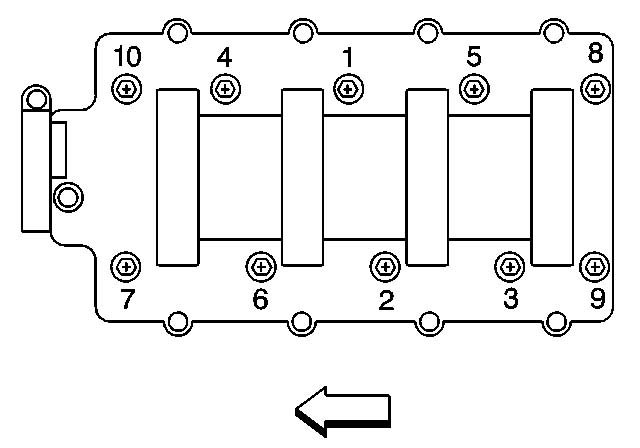

Intake manifold torque sequence. EZ Read simple diagram of the Big Block Chevy Intake Mainfold Torque Sequence. Big Block Chevrolet Intake Torque Sequence. Some Common Intake Manifold Tips.

If you have an old used manifold before installing it check for cracks leaks and the threads in the thermostat. Small Block Chevy Intake Manifold Bolt Torque Specifications 25 FtLbs Make sure you follow the sequence in a couple of steps worry about this more on old and aluminum manifolds. Cast Iron is much more forgiving if you are unfortunate to have to use a boat anchor of an intake.

Torque sequence used for tightening a carbed intake manifold. Chevy SB shown on this videoDisclaimer. To the best of my knowledge this video is accurate.

USS washers should be used with the intake bolts. Install all 12 bolts and washers and torque to 10 lb-ft. Follow torque sequence shown below.

Then using the same torque sequence tighten all 12 bolts to 18 lb-ft for aluminum heads. Repeat multiple times in sequence until all bolts reach proper torque. Tighten the bolts in 2 passes.

See below for torque specs and sequence. Use a quality Torque Wrench. Hook up your vacuum lines andor electrical connections.

If needed install your throttle body and intake tube. LS Intake Manifold Torque Specs. Typically the intake manifold is constructed from aluminum or cast iron.

Intake Manifold to Cylinder Head In the GM 350-cubic-inch engine the intake manifold bolts to the cylinder head with 33 foot-pounds of torque. Too much torque and you risk damaging threads and causing other sorts of headaches. 50HO 302 Intake Manifold Torque Specs.

Lower Intake Manifold to Head Bolts. Use tightening sequence as illustrated above. Upper Intake Manifold to Lower Bolts.

Other Related Torque Specs. Intake Manifold Bolts First Pass in Sequence 5 Nm 44 lb in Intake Manifold Bolts Final Pass in Sequence 10 Nm 89 lb in Intake Manifold Sight Shield Bolts 10 Nm 89 lb in. With the intake manifold in place thread in all the bolts by hand snug them and then torque to 30 ft-lbs following the tightening sequence shown in the Appendix.

I make a habit of going back over the bolts to check the torque after the manifold has compressed the gaskets. The intake gaskets are already installed into the manifold. Be sure to fully seat the injectors into intake manifold when installing the fuel rail.

Failure to do so will result in a vacuum leak andor may prevent fuel rail from being properly attached. There are two sizes of thread-forming screws. The small thread-forming screws are used for mounting the ignition coils.

Tighten to 27 to 33 Nm torque. Apply sealer to the lower intake manifold bolts prior to installation. On the 50L and 57L engines install the bolts and torque in sequence as follows.

Lower intake manifold bolt tightening sequence-50L and 57L engines zoom image link here. 2002 Chevy Avalanche 53L Intake Torque Sequence and InstallACDelco Ignition Knock Sensor - httpsamznto2N0nG4HDorman Knock Sensor Harness - httpsamzn. Head Torque sequence Step 1.

Torque to 50 FtLbs Step 2. Torque to 105 FtLbs recheck final torque in sequence. 12 inchLbs hand tight Step 2.

72 inchLbs 6 FtLbs Step 3. Reinstall intake manifold per shop manual. Tighten intake bolts to 25 nm 18 ftlb.

Use the graphic below for the torque sequence. TECH TIPS This updated manifold does not require additional intake gaskets. The intake gaskets are molded into the manifold.

It is not necessary to replace the hose and. Upper Intake Manifold Click the picture above for the torque sequence 1-6 First Pass 5 lb in. Just enough to spin the bolts on by hand and have some slight tension.

It measures angle of rotation after pre-torque in torque-angle applications. To use the Torque Angle Meter tighten the fastener to the specified torque value using a standard torque wrench. Then install the Torque Angle Meter over the head of the fastener and place the standard wrench onto the top of the Torque Angle Meter.

Lubricate the lower portion of the stud bolts becoming drawn into the intake manifold runners with a light grade oil such as 5W30 and torque resulting in a vacuum leak. The bolts to 14 2 Nm 10 15 lb-ft using the torque sequence shown in Figure 1. ACTION Replace the fuel rail-to-intake manifold paper gasket6.

Replacing the old tried and true small block Chevy engine with a new version would not be an easy task. The new small block is known as the LS engine family and has more than successfully replaced 350s and 305s that were based in design from the 1950s.