The top countries of suppliers are China Taiwan China and India from which the percentage of lead acid battery parts supply is 99 1 and 1 respectively. The gel cell contains a silica type gel that suspends the electrolyte in a paste.

Lead-acid battery construction and process A lead-acid cell is made of three basic components.

Parts of lead acid battery. A tubular lead acid battery uses fiberglass tubes filled with lead oxide and red led powder then sealed with a plastic fitting. The filled tubes are soaked in a diluted acid to convert the lead oxides to lead sulfate. A battery like the MaxHaul line offers an affordable and durable alternative to tubular lead acid.

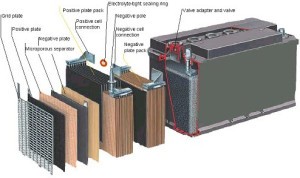

Different parts of a lead-acid battery are as under. A plate consists of a lattice type of grid of cast antimonial lead alloy which is covered with active material. The grid not only serves as a support for the fragile active material but also conducts electric current.

About 60 of the weight of an automotive-type leadacid battery rated around 60 Ah is lead or internal parts made of lead. The balance is electrolyte separators and the case. For example there are approximately 87 kg 19 lb of lead in a typical 145-kg 32 lb battery.

Lead plates are a key part to the development the lead acid battery and have been since they were first developed. Be that as it may the particular development of the plates may shift. A tubular lead acid battery utilizes a similar essential power age systems however is distinctive by they way it is developed.

A tubular lead acid battery utilizes fiberglass tubes loaded with lead oxide and red drove powder at that point fixed with a plastic fitting. There are mainly two parts in a lead acid battery. The container and plates.

Lead Acid Battery Container. As this battery container mainly contains sulfuric acid hence the materials used for making a lead acid battery container must be resistant to sulfuric acid. The material container should also be free from those impurities which are deterious to the sulfuric acid.

Container The container of the lead acid battery is made of glass lead lined wood ebonite the hard rubber of bituminous compound ceramic materials or moulded plastics and are seated at the top to avoid the discharge of electrolyte. At the bottom of the container there are four ribs on two of them rest the positive plate and the others support the negative plates. Most lead-acid batteries are constructed with the positive electrode the anode made from a lead-antimony alloy with lead IV oxide pressed into it although batteries designed for maximum life use a lead-calcium alloy.

The negative electrode the cathode is made from pure lead and both electrodes are immersed in sulphuric acid. Battery Lead Acid Due to missing information on your Hillrom Direct account you are not able to add items to the cart or continue with the checkout process. Please contact our customer support team for further assistance by clicking on contact us.

Lead acid car batteries create electric power using lead plates immersed in sulfuric acid. The reaction creates electricity and another compound called lead sulfate. In a new or healthy battery the lead sulfate produced is usually broken down to lead and sulfuric acid during the charging process.

Not only does this reputable car parts store carry high-quality items but here youll also find some of the lowest prices on battery acid that you could find anywhere else. In fact for less than 10 you can order 32 ounces of acid which should be enough to top off your battery and keep things running smoothly. The top countries of suppliers are China Taiwan China and India from which the percentage of lead acid battery parts supply is 99 1 and 1 respectively.

Sealed Lead Acid Batteries for home AV needs at Parts Express. Available in 13 Ah to 35 Ah. Sealed lead-acid batteries from Power-Sonic Panasonic plus.

Driven by these advantages several types of sealed lead acid have emerged and the most common are gel also known as valve-regulated lead acid VRLA and absorbent glass mat AGM. The gel cell contains a silica type gel that suspends the electrolyte in a paste. Smaller packs with capacities of up to 30A are called SLA sealed lead acid.

Packaged in a plastic container these batteries are used for small UPS emergency lighting ventilators for healthcare and wheelchairs. Recycling lead-acid batteries is the law and is a part of the Battery Act The Mercury Containing and Rechargeable Battery Management Act of 1996. This law was set out to ensure safe recycling of batteries such as lead-acid batteries in order to prevent potential environmental damage.

The lead acid battery has many advantages for automotive and many other uses. They have a large current and surge capability which is ideal when being used to start internal combustion engines. As a technology lead acid batteries are well a well established technology and they can be easily manufactured with relatively low technology equipment.

Construction Parts of a Lead Acid battery. A Lead Acid cell is constructed by immersing the two plates of lead plated with Lead Peroxide and Sponge Lead into the electrolyte Dilute Sulfuric Acid of specific gravity of about 121. The Lead Peroxide and Sponge Lead has very little mechanical strength.

Lead-acid battery construction and process A lead-acid cell is made of three basic components. The electrodes anode cathode and electrolyte. The anode is the negative terminal and the cathode is the positive terminal.

Connecting these is the electrolyte which drives the electrochemical reaction that provides electricity. When a lead-acid battery is not properly recycled lead acid and mercury can be deposited into lakes streams and landfills. Do your part to help eliminate safety hazards in your community by recycling your used vehicle battery today.

Hayward California US has battery recycling locations nearby where you can recycle almost all vehicle batteries.