TORQUE SPECIFICATIONS TORQUE SPECIFICATIONS 43L 50L 57L Application Ft. Im trying to contact RHS as well but havent heard back and Im hoping to have it all together next week sometime.

Intake Manifold to Cylinder Head In the GM 350-cubic-inch engine the intake manifold bolts to the cylinder head with 33 foot-pounds of torque.

Vortec intake torque specs. 43 Vortec Torque Specs Crankshaft. A vehicles engine block usually constructed of cast iron is a collective term referring to the engines. In engines built before 1996 the cylinder head bolts require 65 foot-pounds of torque.

In those built in. Oil Pan and Pump. The bolts of.

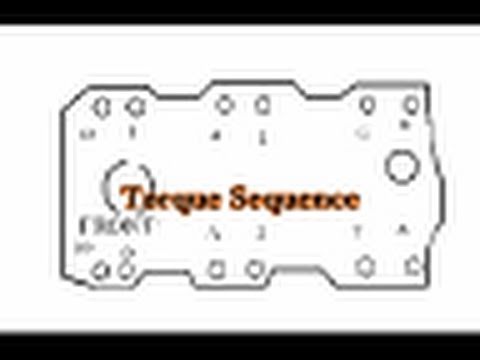

GM Engine Torque Specs. Torque Sequence and Specs. Small Block Chevy Vortec Intake.

Small Block Chevy Engine Specs. Gen VI Big Block Chevy Engine Specs. Subscribe for Exclusive Offers.

Get Exclusive Online Offers. The above combo is the ONLY way to fly on Vortec manifolds. Also clean ALL the old threadlock off of the lower intake manifold bolts and use Permatex Medium Strength 242 Blue threadlock when re-assembling.

With those metal Fel-Pro gaskets you can go up on the torque spec just a bit over the stated spec. It states the intake manifold torque is 35ftlbs. Im going to be using the updated GM vortec manifold gaskets so Im wondering if I should torque to 11 like the stock vortec setup is or to 35 like the RHS spec sheet says.

Im trying to contact RHS as well but havent heard back and Im hoping to have it all together next week sometime. If you use ARP use their specs but The factory specs are 132inlb for the intake to head 88inlb for the upper in steps 27106132 4488 The heads are 22ftlb first Short 55 Med 65 Long 75 The pattern is the traditional from the center out of all SB engines Reusing the stock head bolts is is fine see below From AERA. Torque Specifications for GM 43L-262ci-V6.

Balance Shaft Sprocket To Balance Shaft. Small Block Chevy Intake Manifold Bolt Torque Specifications 25 FtLbs Make sure you follow the sequence in a couple of steps worry about this more on old and aluminum manifolds. Cast Iron is much more forgiving if you are unfortunate to have to use a boat anchor of an intake.

Edelbrock part 7516 RPM Air-Gap intake manifold is based on the powerful Performer RPM Vortec 7116. This single four-barrel intake is designed for 262-400 cid. Chevy V8s with 1996 and later Vortec L31 cast iron or Edelbrock E-Tec aluminum heads.

The torque specification is a 2-step process. Tighten the vertical lower intake manifold bolts the four middle ones to 7 Nm 62 lb in. Tighten the diagonal lower intake manifold bolts two on each end to 7 Nm 62 lb in.

Tighten the vertical lower intake manifold bolts the four middle ones to 13 Nm 115 lb in. Upper intake manifold bolt tightening sequence-1996 74L engines Fig. Upper intake manifold bolt tightening sequence-1997-98 74L engines Access our GM Full-Size Trucks 1988-1998 Upper Intake Manifold Repair Guide Removal and Installation by creating an account or signing into your AutoZone Rewards account.

At the 364 cubic inches of displacement the engine is rated at a respectable 360 peak horsepower and 380 lb-ft peak torque. More importantly the engine features a relatively broad flat torque curve and a linear horsepower curve that grows sharply. Typically the intake manifold is constructed from aluminum or cast iron.

Intake Manifold to Cylinder Head In the GM 350-cubic-inch engine the intake manifold bolts to the cylinder head with 33 foot-pounds of torque. Outer Main Cap Bolt. Inner Main Cap Bolt.

Outer Main Cap Bolt. Screw-In Rocker Arm Studs. Intake Manifold Bolts Cast Iron Heads 30 ft-lbs.

Intake manifold bolts 18 ftlbs The degrees you see are the torque angle method. You need to basically torque them down in sequence to the first step then go back through and torque them down to the next step. Then you turn them the specified angle in sequence and do that until all the steps are done.

TORQUE SPECIFICATIONS TORQUE SPECIFICATIONS 43L 50L 57L Application Ft. Nm Balance Shaft Gear Bolt Step 1 15 20 Step 2 Additional 35 Degrees Bellhousing Bolt 35 47 Camshaft Sprocket Bolt 18 25 Connecting Rod Cap Nut 43L Step 1 20 27 Step 2 Additional 70 Degrees 50L 57L Step 1 20 27 Step 2 Additional 55 Degrees. So intake manifold gasket it is.

Total job took 15 hours. 8mm and 10mm sockets various 14 drive extensions 14 ratchet couple picks flathead screwdrivers and a torque wrench for inch-lbs I used my Wheeler gunsmithing wrench. Youll also need a fuel line connector puller.